During this webinar, PowerHub and Sitemark explored the irrevocable effects of digitalisation on the solar industry and more specifically in terms of Asset Management and O&M.

PowerHub’s Product Director, James Pagonis, reflected on the landscape of digitalisation trends in the industry and the significance of centralised data. Vishal Punamiya, CEO of Sitemark (f.k.a Dronegrid), highlighted the specific impact of going digital on site inspection. Particularly, the use of aerial data captured by drones and its implementation by large enterprises to digitise their sites and successfully incorporated into operational workflows and decision-making processes.

1. Centralising information and improving asset management efficiency

Pagonis started by underlining the divergence of initial expectations held in the renewable industry as well as the changes in the regulatory, financial, environmental and health compliance. These all require a substantial amount of time to manage and consequently relevant tools to make that possible. He adds that old systems do not scale well since they involve people to keep patching these processes together. The heavy human intervention with these systems leads to a glut of duplications, missing information and redundant work as the the same information is stored in various places. Furthermore, as the asset processes grow in complexity, the old systems at some point will no longer be able to deal with that complexity. This all results in:

- Slow decision-making

- Lack of transparency

- Difficult coordination- especially for asset managers coordinating not only internally but with external third parties

"When digital transformation is done right, it’s like a caterpillar turning into a butterfly, but when done wrong, all you have is a really fast caterpillar."

George Westerman | Principal Research Scientist with the MIT loan Initiative on the Digital Economy

One of the important goals of digitalisation is risk mitigation, which directly affects efficiency and downtime. This is mainly beneficial in the case of solar PV systems as their maximum financial returns are dependent on the maximum theoretical performance associated with them. Therefore, ensuring consistent output as expected is a key result of the risk mitigation process. Another side effect of digitalisation is its likelihood to supply new opportunities to the teams with a digitalisation process, enabling them to spend a lot less time collecting data and analysing them.

1.1 Where To Begin & Things To Consider

“There is value of software at all sorts of different scales whether you’re doing 10 projects or two gigawatts of projects,” explained Pagonis. He added that this value varies depending on project complexity with regards to portfolio and not the project. The value of digitalisation rises exponentially as the portfolio grows in complexity.

In PowerHub’s experience, potential clients present typically a spreadsheet with a lot of numbers and list of their desirable outcomes. According to Pagonis, this is a premature approach. It is much more effective to create a list of the day-to-day problems, you are trying to solve and sort them based on priority. This enables you to choose the right software(s), which addresses your specific needs. Another point to consider would be to conduct some introspection and analyse your existing data in order to reap the most benefits out of the software. At last, in Pagonis’ words “Let the software surprise you!”.

2. Aerial Inspection & Key Points To Consider

Sitemark’s inspection approach starts by identifying the expected outcome first, which affects the process of image acquisition and the planning of operations. These factors in return influence how data is captured, analysed and processed.

2.1 Site Surveying

Utilising Sitemark’s expertise from the mining sector, one of the very basic points is to have an accurate understanding of site topography, on which the project is expected to be built. Other basic parameters of a platform that greatly lowers project risks, include:

- Improved costing and planning

- Digital modeling based on accurate data

- Significant reduction in project risks and budget overruns

2.2 Engineering Phase

Punamiya provided an example of a roof-based site as they tend to be although smaller, nonetheless more resource-intensive, specifically during the planning and engineering phase. He explained that Sitemark’s solution automatically creates a CAD model from a point cloud, which is very unique in the solar space as most solutions require manual operation for creating a CAD model from the point cloud. Other benefits during the engineering phase are:

- Significant reduction of manual work (4x—8x reduction in effort)

- Digital modeling based on accurate data

- Reduction in project costs and improved safety

2.3 Construction Phase

The key consideration of this stage is the comparison between the CAD model versus the as-built model. It is possible to upload your CAD model onto the Sitemark platform, based on which and the captured image data, it can be identified whether the panels are within tolerances, the angles, etc. Ultimately, it is important to be able to compare and communicate across various stakeholders despite any potential limitations like geographical distance.

2.4 Operations Acceptance & Maintenance Phase

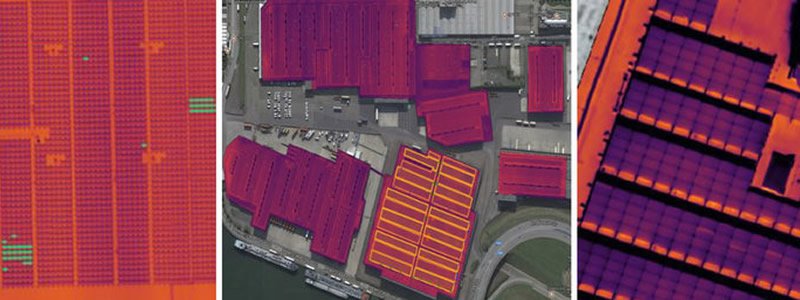

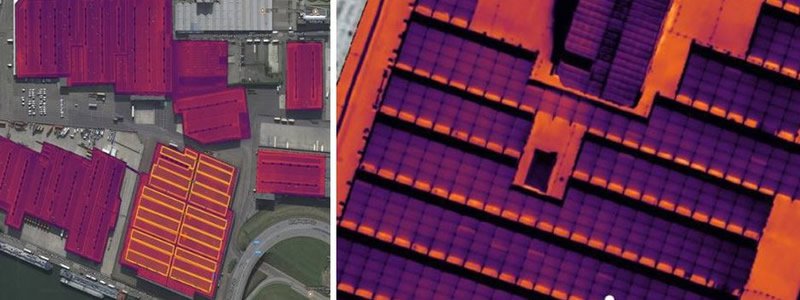

According to Punamiya, what is proprietary to Sitemark is that for every solitary pixel is captured from 6 different positions while the drone is flying on its normal route. The rationale behind doing this is that the image processing software automatically spots a pixel with lens glare or reflections and substitutes it with the same pixel, caught from a different angel. This enables an automatic removal of lens glare while ensuring the final data is distortion-free, resulting in highly-accurate and successful detection rate of anomalies. Punamiya also noted that “We do not normalise temperature so we are able to capture raw data at a pixel level up to 0.1 degrees in accuracy”. To provide an example, on the image below, several issues can be observed, which require to be fixed before it is ready for handover.

Some additional points of consideration with respect to aerial inspection are:

- Easy to use and deploy

- Quality & Compliance (IEC TS 62446-3:2017)

- Interoperability with inhouse systems

- Collaboration and Bespoke Tools

- Wide range of asset size (200kw - 200mw)

- Geographically scalable

2.5 Case Studies

Roof-mounted: Customer with 150 MW installed across 185 roofs. Statistically significant bypassed diode issues across entire site were identified, which turned out to be a manufacturing issue.

Ground-mounted: Customer with 3.5 GW portfolio installed across 140 sites in 14 countries. Statistically significant PID issues were observed across one entire site. The interesting observation was that these issues were happening on both the negative and positive side of the string. Sitemark enables their clients to ask the right questions from their O&M service provider and EPC, when faced with such anomalies.

2.6 Why Is Automation Key?

In the case of Sitemark, automated processes are the backbone of their platform, a few of which entail:

- AI & Machine learning based methods on a combination of thermal and RGB images

- Localization and classification (String, PID, vegetation, soiling, diode issues, junction box, etc.)

- Online and completely digitized, providing the ability to correlate different types of issues with certain potential root causes, for instance comparing multiple vendors based on the issues observed.

Last point is interoperability, which boils down to the ability to work with multiple data sets, for example importing string maps, and the ability to collaborate on a single source of truth. More importantly, the ability to compare different variables, ultimately supplying the client with better insights on their site.